Blister Pack Packaging Solutions

Our Blister Packaging Solutions

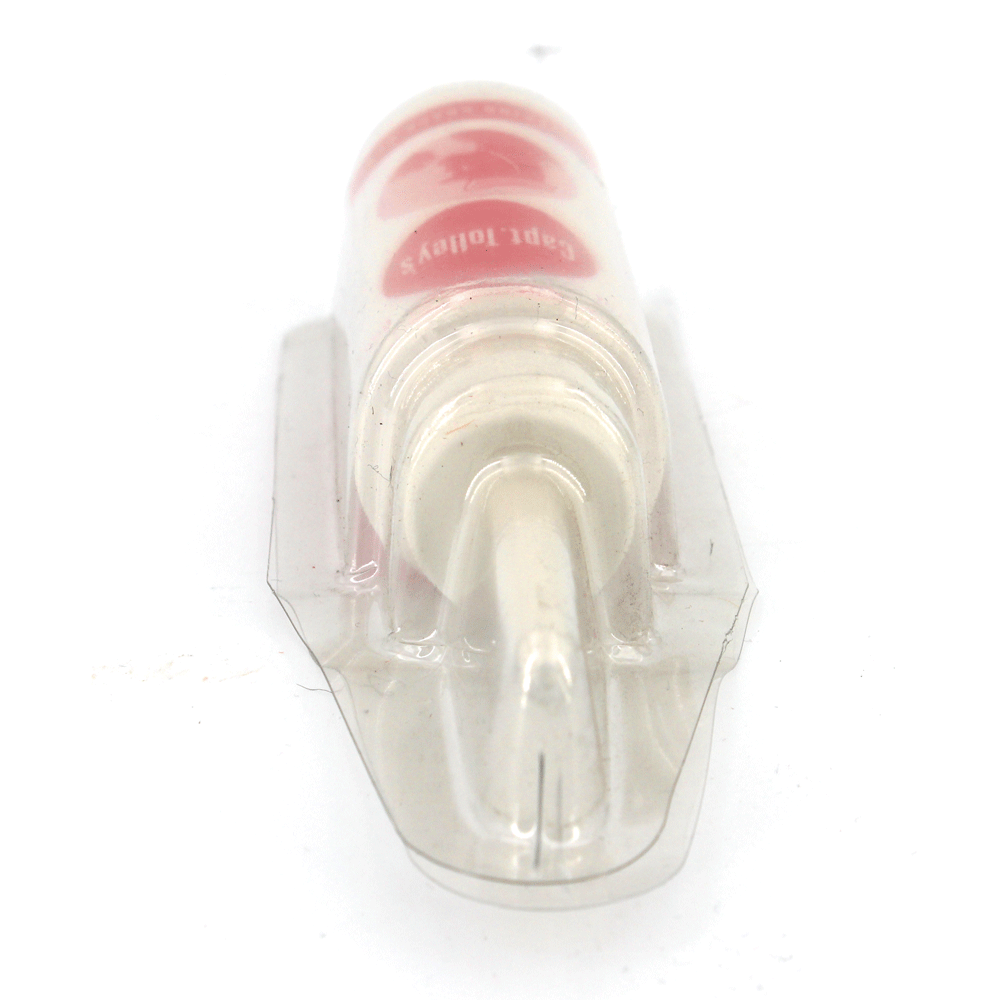

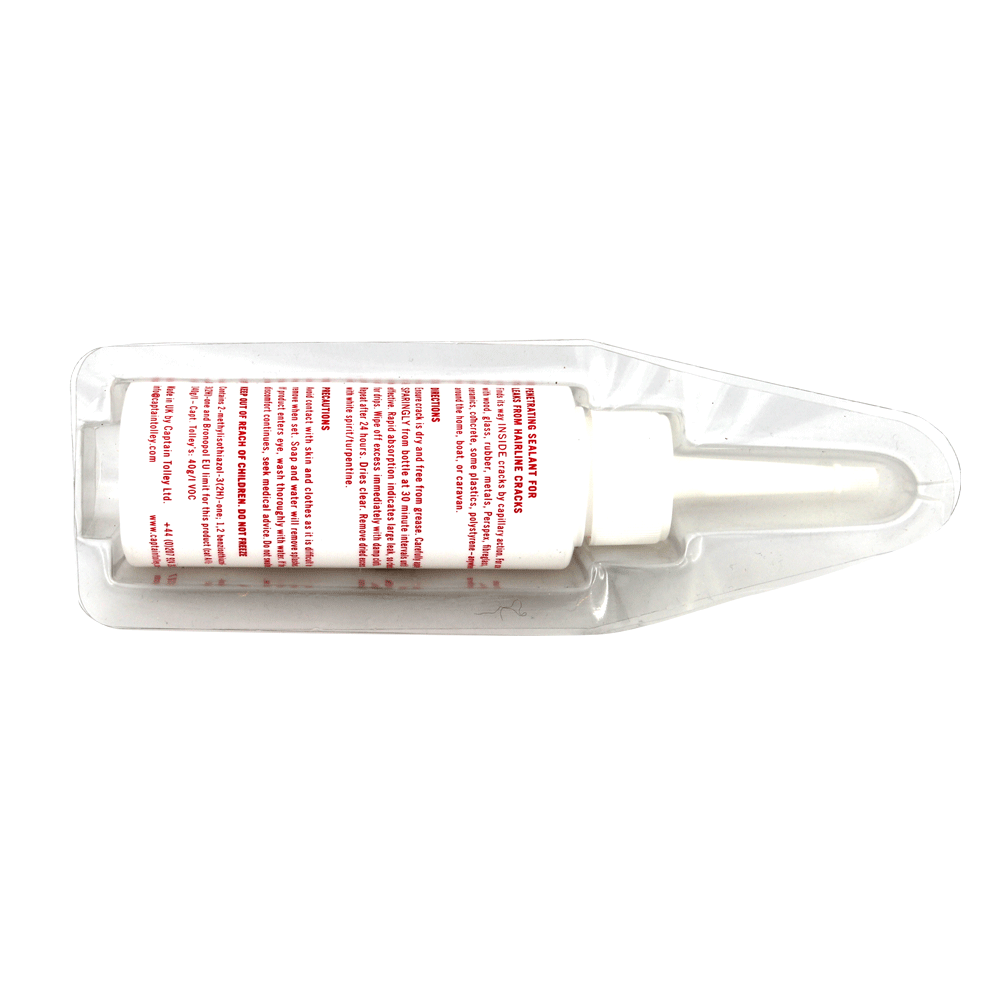

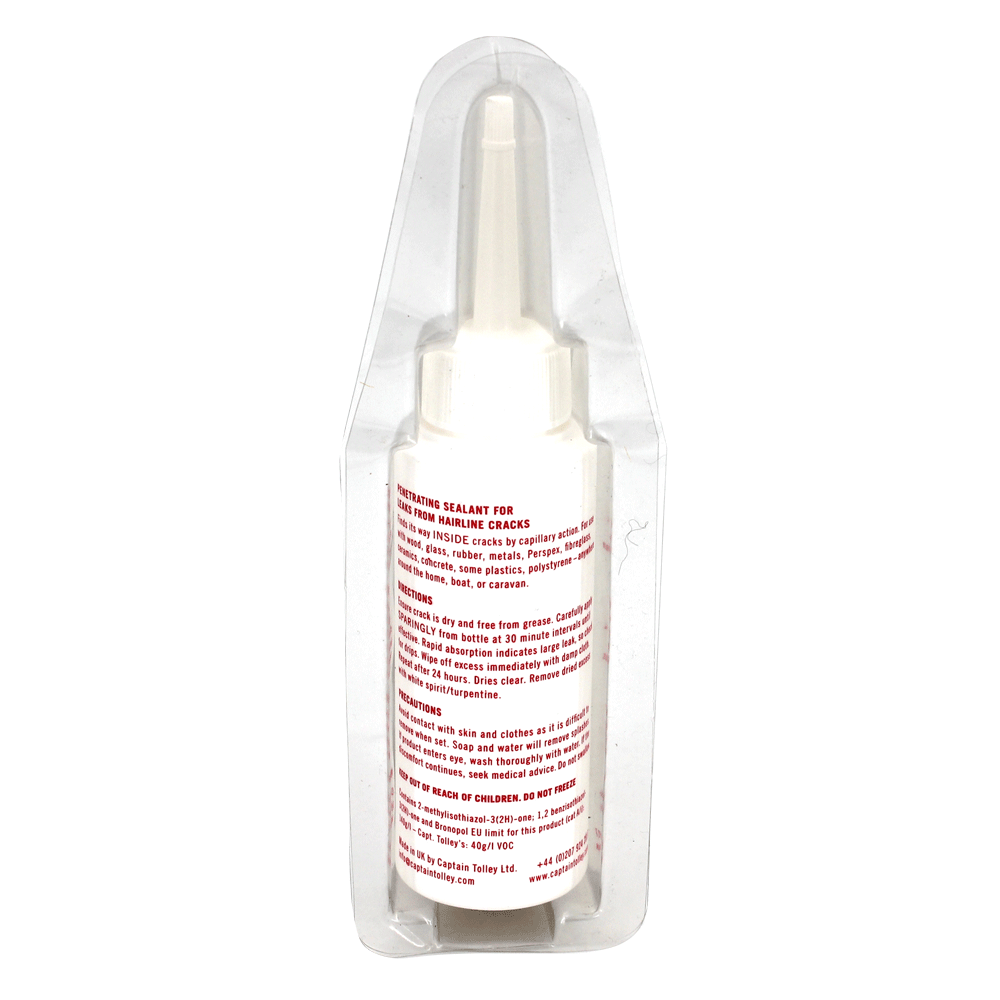

Blister pack packaging is also referred to as blister sealing, blister packing, blister heat sealing, or trapped blister packing. Blister Packs are individually made blisters (see Thermforming) that are heat-sealed to the face of a coated backing card or the blister is trapped between front and back cards.

Blister Packs can be tailored to meet your specific requirements, with bespoke blisters made and heat-sealed in APET/RPET/PVC material up to our maximum card size of 420 x 380mm. There is no minimum order quantity and we can cope with capacities up to 100,000 units per day.

We operate to the highest sustainability standards – all our blister packs use 85% recycled RPET material that is 100% recyclable – thus does not incur any packaging tax, and last but not least, we generate 50KwH of our own electricity every day from a Solar Panel array on the roof.

Customization in Blister Pack Packaging Product Design

- Bespoke packs to your specification, including Euroslot for hanging

- Max card size of 420x380mm

- Will not incur new packaging tax

- Your product is protected and secure until the point of usage.

Benefits of Blister Packing Contract Expertise

The advantages of Blister Sealing are that it is very economical for medium to larger quantities as well as being very secure for protecting your products against external damage. Blister Backing Cards also present excellent opportunities for branding and normally feature a Euroslot for shelf hanging. We can arrange for the backing card to be printed from your own artwork.

All of our blister packs are made of 85% Recycled RPET material, they are also 100% recyclable. So they are not only greener, they will not incur the new packaging tax.

Sustainability in Our Blister Packs Packaging Process

Platt Packaging can offer a start to finish Blister Packing/Sealing service from our site in Tredegar in South Wales. This service includes…

- Thermoforming of the Bespoke blister

- Backing card printing

- Blister heat sealing

- Nationwide delivery

Secure sustainable packaging with our customised blister pack packaging solutions